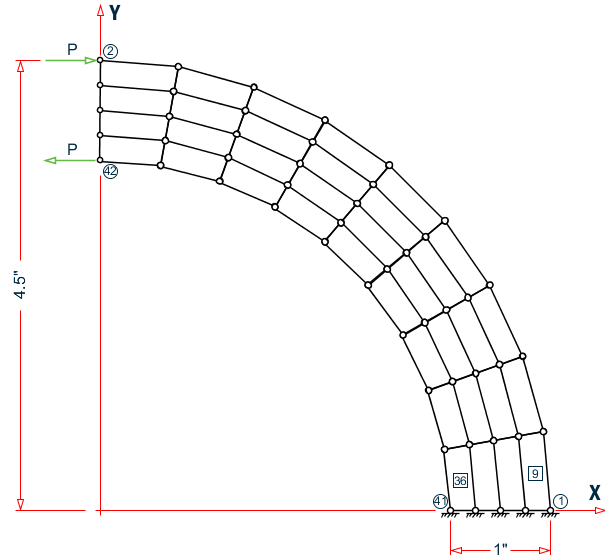

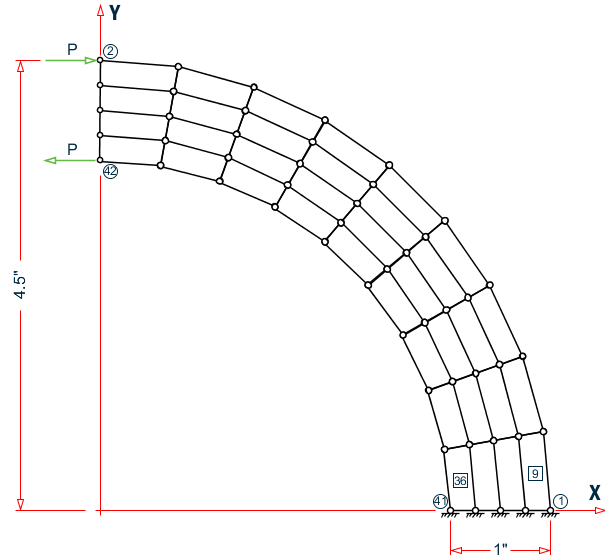

Using plate/shell elements, find maximum bending stress

due to a force couple on a curved cantilever beam.

Reference

Timoshenko, S.,

Strength of Materials, Part I, 3rd Edition, Van

Nostrand Co., 1956.

Problem

Find the maximum bending stress

Cantilevered, curved

plate with coupling load at free end

Comparison

Table 1. Comparison of results

| Result Type

|

Theory

|

STAAD.Pro

|

Difference

|

Comments

|

| Plate Corner Stress at Node 41 (psi) |

655.0

|

636.02

|

2.9%

|

The result from the Beam theory is

compared with the result from a Finite Element Model output, hence the

difference in results.

|

| Outside stress (psi)

|

555.0

|

556.73

|

negligible

|

|

STAAD Output

SUPPORT REACTIONS -UNIT POUN INCH STRUCTURE TYPE = SPACE

-----------------

JOINT LOAD FORCE-X FORCE-Y FORCE-Z MOM-X MOM-Y MOM Z

1 1 -15.30 61.91 0.00 0.00 0.00 -2.09

11 1 3.80 69.53 0.00 0.00 0.00 0.72

21 1 12.47 5.36 0.00 0.00 0.00 1.21

31 1 11.58 -66.95 0.00 0.00 0.00 1.75

41 1 -12.55 -69.85 0.00 0.00 0.00 -1.59

************** END OF LATEST ANALYSIS RESULT **************

52. PRINT ELEMENT JOINT STRESSES LIST 9 36

ELEMENT JOINT STRESSES LIST

:CURVED BEAM WITH PLATE ELEMENTS -- PAGE NO. 4

ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH

----------------

STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH

ELEMENT LOAD SQX SQY MX MY MXY

VONT VONB SX SY SXY

TRESCAT TRESCAB

9 1 0.00 0.00 0.00 0.00 0.00

432.15 432.15 -433.11 -2.49 8.94

433.30 433.30

TOP : SMAX= -2.31 SMIN= -433.30 TMAX= 215.50 ANGLE= 88.8

BOTT: SMAX= -2.31 SMIN= -433.30 TMAX= 215.50 ANGLE= 88.8

JOINT 0.00 0.00 0.00 0.00 0.00

10 592.15 592.15 -560.35 58.12 15.37

TOP : SMAX= 58.50 SMIN= -560.73 TMAX= 309.62 ANGLE= 88.6

BOTT: SMAX= 58.50 SMIN= -560.73 TMAX= 309.62 ANGLE= 88.6

JOINT 0.00 0.00 0.00 0.00 0.00

1 527.90 527.90 -556.47 -63.65 11.40

TOP : SMAX= -63.39 SMIN= -556.73 TMAX= 246.67 ANGLE= 88.7

BOTT: SMAX= -63.39 SMIN= -556.73 TMAX= 246.67 ANGLE= 88.7

JOINT 0.00 0.00 0.00 0.00 0.00

11 285.05 285.05 -310.91 -64.85 13.47

TOP : SMAX= -64.11 SMIN= -311.65 TMAX= 123.77 ANGLE= 86.9

BOTT: SMAX= -64.11 SMIN= -311.65 TMAX= 123.77 ANGLE= 86.9

JOINT 0.00 0.00 0.00 0.00 0.00

20 351.99 351.99 -318.48 58.96 8.48

TOP : SMAX= 59.15 SMIN= -318.67 TMAX= 188.91 ANGLE= 88.7

BOTT: SMAX= 59.15 SMIN= -318.67 TMAX= 188.91 ANGLE= 88.7

36 1 0.00 0.00 0.00 0.00 0.00

457.10 457.10 473.43 34.66 2.24

473.44 473.44

TOP : SMAX= 473.44 SMIN= 34.64 TMAX= 219.40 ANGLE= 0.3

BOTT: SMAX= 473.44 SMIN= 34.64 TMAX= 219.40 ANGLE= 0.3

JOINT 0.00 0.00 0.00 0.00 0.00

40 314.58 314.58 298.80 -24.94 -23.18

TOP : SMAX= 300.45 SMIN= -26.59 TMAX= 163.52 ANGLE= -4.1

BOTT: SMAX= 300.45 SMIN= -26.59 TMAX= 163.52 ANGLE= -4.1

JOINT 0.00 0.00 0.00 0.00 0.00

31 247.25 247.25 282.26 108.74 10.51

TOP : SMAX= 282.90 SMIN= 108.11 TMAX= 87.39 ANGLE= 3.5

BOTT: SMAX= 282.90 SMIN= 108.11 TMAX= 87.39 ANGLE= 3.5

JOINT 0.00 0.00 0.00 0.00 0.00

41 594.55 594.55 634.80 95.42 25.72

TOP : SMAX= 636.02 SMIN= 94.20 TMAX= 270.91 ANGLE= 2.7

BOTT: SMAX= 636.02 SMIN= 94.20 TMAX= 270.91 ANGLE= 2.7

JOINT 0.00 0.00 0.00 0.00 0.00

50 680.99 680.99 656.97 -43.84 -21.63

TOP : SMAX= 657.64 SMIN= -44.51 TMAX= 351.08 ANGLE= -1.8

BOTT: SMAX= 657.64 SMIN= -44.51 TMAX= 351.08 ANGLE= -1.8

:CURVED BEAM WITH PLATE ELEMENTS -- PAGE NO. 5

**** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES ****

MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM

PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA

STRESS STRESS STRESS STRESS STRESS

6.576412E+02 -5.607280E+02 3.510752E+02 4.571006E+02 4.734368E+02

PLATE NO. 36 9 36 36 36

CASE NO. 1 1 1 1 1